Instruction of diesel generator set

1. Configuration and parameters of the unitUnit model:

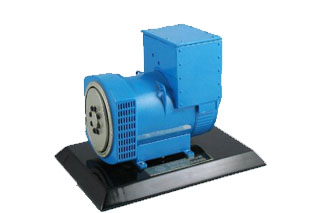

Alternator:

Diesel engine:

Control screen:

Rated power: rated voltage: rated current:

Rated frequency: power factor: rated speed:

Phase number connection method:

Two. Characteristics and uses of the unit

Our factory is the cradle of China's generating set. It is the first enterprise to develop and produce generator sets. The diesel generator set (power range 3 ~ 1000KW) is the main product of our factory. It combines the advanced technology of the production technology of synchronous generator, excitation device and overall structure in our factory, and uses the national standard 95, 135, 160, 190 series of diesel engines and the United States Cummings, Austria Staier, which introduced the international name. And diesel engines, such as the rich imported from Sweden, and so on. The products are superior in quality and advanced in technical performance, which can provide stable, reliable and economical power for customers at home and abroad.

Diesel generating set is an AC generator set, which runs smoothly, durable and easy to maintain. It is suitable for industrial and mining enterprises, hotel hospitals, rural towns, fishing and animal husbandry to make power lighting, mobile or fixed power supply for communication and broadcasting, and can also be used as a standby power source for buildings and hotels.

When the rated power of the unit is 0 to 100% and COS 0.8, the automatic voltage adjustment rate under the three-phase symmetrical load can meet the general requirements and can be adjusted in the range of 95 to 105% of the rated voltage when no load is loaded. The unit can directly start the squirrel cage three-phase asynchronous motor of the rated power of the 30 ~ 70% unit. When the unit operates under the unbalanced three-phase load, if the per phase current is not more than the rated value, and the three-phase current is not more than 20%, the unit allows long-term work.

Three, the use environment of the unit

The unit can operate continuously for 12 hours and output power under the following environmental conditions.

1. Ambient temperature: 5~40 C

2. Relative humidity: 85% (25 C)

3, altitude: "1000 meters"

4. The longitudinal inclination of the working time: "10 degrees

5. There is no conductive dust and corrosive gas that destroys metal insulation.

Be careful:

1. The rated power (the capacity of the unit) is the output power allowed for 12 hours in a continuous period of 12 hours (including 1 hours of excess load 10%), under the conditions of ambient temperature 20, relative humidity, 60%, and high atmospheric pressure of 760 mm Hg.

The output power of the generator must be trimmed when working under the above environmental conditions.

2. When the unit runs continuously for more than 12 hours, it will be converted to 90% according to its output power (i.e., lasting power). If the above conditions are exceeded, the lasting power is also calculated at 90% of the corrected power.

3. The diesel generating set is used under the circumstances stipulated in the above 1, 2, and 3. The output power can also be amended according to the specification of the diesel engine.

Four. The storage and installation of the unit

The storage, installation and location of diesel generators should meet the following requirements:

1, the room is spacious and bright, well ventilated, low humidity, ambient temperature of 40 C;

2, night work should have good lighting equipment, outdoor use should be added protective cover, to avoid rain and exposure.

3, the environment should be clean. No acid, alkaline and other corrosive gases should be placed around it.

4, the exhaust pipe of diesel engine should be unblocked, avoid the pipeline being too long or suddenly turning. When the exhaust pipe is connected to the outside, it is advisable to tilt the outer tube a little, so that the condensation water will flow out of the pipe.

5. If the unit is not fixed on the foundation, rubber plates can be used under the chassis to reduce vibration.

6, installation of units above 30KW should do the following:

1) the foundation is all concrete, but the foundation must not be linked to the building foundation. The distance of the building wall to the unit is not less than 1.5 meters.

2) when installing, the horizontal level must be measured to ensure that the unit is fixed on the horizontal position.

3) for personal safety, the generator and switch screen must be connected to the ground wire, and the area of the ground wire shall be no less than the cross section area of the generator output line. The ground wire can be connected to the underground water pipe or deep buried steel plate to ensure good grounding and the earth resistance should not exceed 50 ohms.

4) open cooling units must be installed with cooling water pipes to ensure adequate supply of cooling water.

5) in order to reduce environmental noise, external noise elimination devices can be installed.

6) the main axis of the generator should be less than 0.15 millimeters to the main shaft of the diesel engine after installation, and the pulsation of the axis of the generator should generally be less than 0.5/400.

7) the battery should be connected to the starting and charging circuit diagram according to the instructions for maintenance and operation of diesel engines.

Five, the use of the unit

Before using the unit, it is necessary to read the maintenance instructions of the unit and the maintenance instructions for the diesel engine, generator and control panel carefully.

1. Preparation before starting

1) clean the foreign matter such as dust, water stains and rust that are attached to the unit, and remove the dirt from the air filter.

2) check the whole unit of the unit thoroughly, the connection should be tightened, the control mechanism should be flexible, and the crankshaft rotation should not be stuck.

3) check whether the cooling system has been filled with coolant, and whether the pump is filled with suction water. Whether there is leakage or obstruction (including gas resistance) in the pipeline;

4) check the fuel stock of the fuel tank, turn on the fuel switch, unscrew the high-pressure gas pump vent bolts, remove the air in the fuel pipeline, and tighten the bleed bolts.

5) check whether the oil surface is between the scale of the oil gauge two and whether the fuel pump and governor have enough oil.

6) check the reliability and flexibility of the connection between the governor lever and the oil pump rack, and check whether there is enough oil at the same time.

7) check whether all electrical lines (including charging and starting circuits) are properly connected and have good contact.

8) check whether there are leakage and oil leakage in each pipe joint of diesel engine such as supply, lubrication and cooling system.

9) all components in the control panel should be complete, clean, no damage and no loosening.

10) to disconnect the silicon rectifier, capacitor and so on, and to dismantle the ground wire with 500 volt megabytes to determine the insulation resistance of the first line and the rotor winding to the ground insulation resistance should be less than 3 mega, otherwise the drying measures should be taken.

11) the wiring of the generator to the switch screen should be correct. The negative transplanting is connected to the control screen by the double switch switch. It should be isolated from the power grid (air circuit breaker should be in a short circuit position; the generator U, V, W and the control screen bus).

12) check whether the position of each switch on the control panel is normal, the main switch should be divided, and the control panel with automatic voltage adjustment should be placed in manual position.

13) instrument (except for frequency meter) pointer should be zero.

2, the start of the unit

1) switch the screen up pressure selector switch in manual position.

2) turn on the fuel switch and fix the fuel control handle at the throttle position about 700 R / s.

3) use the high pressure oil pump switch handle continuously to manually pump oil until the pump oil resistance and the fuel injector emit a crisp squeak.

4) put the oil pump switch handle on the working position, and the pressure relief valve is pushed to the decompression position.

5) the diesel engine is started with the hand handle or the electric start button. When the diesel engine reaches a certain speed, the reducing axis is quickly pulled back to the working position and the diesel engine is started to start the ignition.

6) after starting the diesel engine, the electric key should be transferred back to the middle position, the speed should be controlled at 600~700 turn / points, and the oil pressure is closely observed. The indicator of the table (the working oil pressure value is detailed in the instruction of various diesel engines). If the oil pressure is not indicated, it should be stopped immediately.

7) if the unit is running normally at low speed, the speed can be gradually increased to 1000~1200 rotating / preheating operation. When the water temperature is at 50~60 C and the oil temperature reaches about 45 C, the speed increases to 1500 turn / points, and the distribution screen frequency meter should be around 50 hertz, the voltmeter is 380~410 volts, if the voltage is high or low. Adjustable magnetic field rheostat;

8) if the unit works normally, it can close the air switch between the generator and the negative planting, then gradually increase the negative planting and send electricity outward.

Note: 1) all types of diesel engines should be started according to their requirements for use and maintenance of diesel engines.

2) in the time of pressure regulation, if the unit is stored too long, the generator is lost, the voltage can not be set up, the battery can be magnetized at this time, and the magnetic field winding L1 (+) connects the positive pole L2 (-) to the negative electrode of the battery when the magnetic field is magnetized.

3) if the button is pressed for 10 seconds, it can not start the ignition and should wait for a minute or so to start second times. If the failure is continuous for three times, the cause of the failure should be found out again.

3. Operation of the unit

1) trial rotation of a new unit

After installing the new unit, the following procedures are tried out:

Sequence power (% rated power) speed (transfer / minute) time (points) remarks

1080020 stop the engine to check the oil temperature.

225150030 no overheating.

350150030

475150030 stop the machine to check bearing.

5100150080 no abnormalities, and more

6110150060 oil change

2) operation of the unit

1) after the operation is stable, the load should be increased gradually, and no negative planting should be avoided.

2) should always pay attention to the oil pressure, temperature, water temperature and the indicator values of each instrument on the switch screen should be within the range of various diesel engines and generator instructions.

3) regularly check the adequacy of fuel, oil and cooling water.

4) the new unit must operate at minus 90% of the rated power for 4 hours before being able to operate at rated power and rated speed.

5) the output power of the unit should be revised according to the regulations if the operating environment is beyond the allowable conditions.

6) the following matters should be paid attention to in operation:

Pay attention to the change of water temperature, oil temperature and oil pressure at any time. If it is not normal, check the oil, oil, cooling water and the cleanliness of cooling water regularly. At the same time, check the oil leakage, leakage, leakage and other abnormal phenomena of the diesel engine, and observe the abnormal color of the exhaust gas of the diesel engine. If gray blue, dark blue, black should be stopped for inspection, strictly prohibit water, oil, metal or other foreign matter from entering the motor, and the three phase voltage of the motor should be kept balanced.

7) a detailed record should be recorded in the operation, including the parameters of the environment state, the operating parameters of the oil machine, the opening time, the shutdown reason of the shutdown time, the cause of the failure, the elimination method, the name and quantity of the replacement parts.

4. The shutdown of the unit

Taking large units as an example, the following is described as follows:

1) normal shutdown

1) gradually remove the negative planting, disconnect the negative switch and transfer the commutation switch to the manual position.

2) the rotation speed is reduced to 600~800 R / min after empty planting. After running for several minutes, the oil pump handle is stopped to stop supplying oil, and the handle is reset after stopping.

3) when the ambient temperature is less than 5 degrees, the cooling water of the pump and diesel engine should be exhausted.

4) the speed control handle is placed at the lowest speed, and the voltage switch is placed in the manual position.

5) short term parking does not turn off the fuel switch to prevent air from entering the fuel system.

6) long term parking must be put out of oil;

2) emergency shutdown

An emergency shutdown must be made when the following conditions occur. At this point, the negative planting should be cut off, and the fuel pump switch handle will be transferred to the cutting off oil line immediately, so that the diesel engine will stop immediately.

The pressure meter of the unit decreased to below the specified value.

1) the temperature of cooling water is more than 99 degrees C;

2) a sharp knock on the unit or damaged parts.

3) cylinders, pistons, speed regulators and other moving parts are stuck.

4) when the voltage of the generator exceeds the maximum readings on the table;

5) when fire or electricity leakage and other natural hazards occur;

Six. Maintenance and maintenance of the unit

Diesel generators are made up of different types of diesel engine, generator control panel and other main parts. All main parts have their own maintenance requirements. In order to ensure proper maintenance of the unit, all parts should be maintained regularly according to their respective maintenance instructions.

The unit should be serviced once a week during regular or short-term parking. The maintenance items are as follows:

1) clean up the parts of the unit and wipe away the dust and grease from the parts.

2) check the connection of electrical components and wires, eliminate the malpractice of contact or short circuit.

3) check the unit, whether the mechanical connection parts are solid and reliable, and whether the lubrication is good.

The general maintenance of the generator is as follows:

1) avoid dampness of motor and store it in dry place.

2) no matter when storing or running, it is necessary to avoid water droplets, metals and other debris entering.

3) when the generator is running, attention should be paid to the cooling condition, and the voltage and current should not exceed the rated value.

4) during operation, no more than 1.5 millimeter spark should be seen on the collector ring, and the temperature of the collector ring should not exceed 80 C.

5) if abnormal noise is heard, stop and check immediately.

6) do not use the motor under water vapor or dusty conditions.

7) after 3000 hours of bearing work, oil should be supplemented and No. 3 compound calcium base grease. The amount of oil should be half of the oil storage room. The oil should be cleaned and the temperature of bearing should not exceed 95 C.

8) check whether the components of the excitation device are broken or loosened.

The diesel engine is required according to the requirements of the maintenance manual for diesel engines.

Seven, the failure and elimination of the unit

1) no power generation

1. loss of remanence and 1. for magnetization

2. magnetic field circuit short circuit 2. repair

3. diesel engine speed is too low 3. adjust the speed, maintain the rated value.

4. silicon rectifier diode damaged 4. check replacement rectifier diode

5. loose connection or bad contact of control panel 5. tighten thread.

6. fuse fuse 6. change

7. open circuit of three harmonic winding and 7. short circuit repair

8. magnetic field rheostat circuit, open circuit 8. repair

2) voltage abnormal

1. the high or low speed of the diesel engine is adjusted to a fixed value of 1.

2. silicon rectifier diode damaged 2. replacement

3. brush contact bad 3. cleaning ring surface, 00 sand cloth grinding brush surface, strengthen the brush spring pressure.

4. voltmeter is not allowed 4. to check the meter or change

5. external circuit short circuit 5. elimination

6. fuse break 6. change

3) superheating of the generator

1. pass three phase current imbalance, 1. pay attention to current readings at any time, adjust three-phase negative current immediately.

2. magnetic field coil short circuit 2. check or change

3. diesel engine low speed 3. increase speed to rated value

4. ventilation duct obstruction or fan damage 4. blows inside, dredge air passage, overhaul fan.

4) voltage difference

1. transmission line too far (low voltage) 1. adjust manual rheostat.

2. transmission line close (high voltage) 2. adjust manual rheostat

5) difficult start or incipient start

1. starter motor damage 1. change or repair starting motor

2. less than 2. of battery storage and sufficient battery charging.

3. lack fuel or fuel less than 3. add fuel, switch on.

4. the fuel quality is not up to the requirement or there is water in the fuel 4..

5. oil pump advance angle is not 5., adjust the oil supply advance angle according to the regulations.

6. air filter sewage plugging 6. clean clean

7. diesel oil temperature is too low 7. heating water and heating oil.

8. long idle operation 8. clearance carbon deposition, cleaning fuel injector.

6) sudden stop

1. fuel free 1. add fuel in the fuel tank

2. fuel mixed with moisture 2. to identify causes and replace fuel.

3. injection pump spring break 3. replacement spring

4. speed governor spring break 4. change speed spring

5. piston biter 5. replacement of piston and related parts

6. connecting rod bearing bush, main shaft bearing burnt 6., dismantling and replacing parts.

7. timing gear or fuel injection pump timing mechanism damage 7. check and replace parts.

Note: the above troubleshooting methods are for reference, mainly by the exclusion of the instructions for the maintenance of the generator, the instructions for maintenance of the diesel engine, and the instructions for the use and maintenance of the control panel.

Appendix

After-sale service of the unit:

1) the unit will be insured for one year from the date of delivery, and the unit will be kept for 1500 hours continuously; the two shall be first served.

2) the cost of material cost is charged during the period of over insurance. County and other provinces and cities should collect traffic fees as appropriate, free of charge in the city.

Appendix

It

Generator assembly box:

It

1, diesel engine (with fan, radiator tank, public chassis) sleeve.

2. Generator station

3, unit control panel

4, unit maintenance instructions

5. Diesel engine, generator and control panel.

6. The certified copy of the unit for inspection

7. Unit starting battery (12V) only

8. The unit silencer only

9, unit fuel tank (for hours work) only

10, unit maintenance tool set